- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Did you know that tungsten carbide dies can enhance both precision and durability in manufacturing? These tools shape metals at room temperature while maintaining strength and reducing waste.

In this article, we will explore how tungsten carbide dies are used in cold extrusion and cold forming. We’ll cover their benefits, real-world applications, and how they boost efficiency, reduce downtime, and improve part consistency.

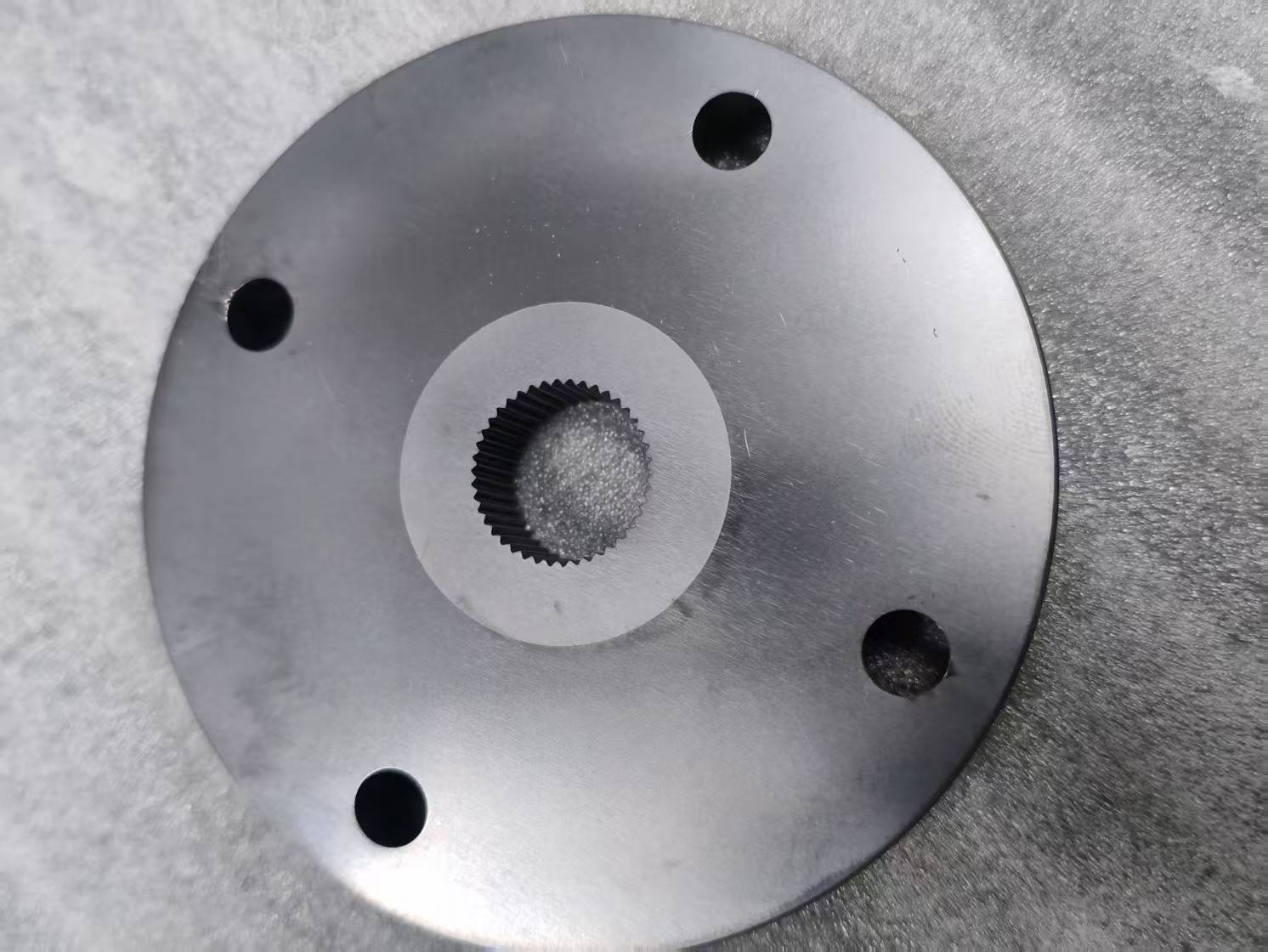

Tungsten carbide is widely regarded as the best material for cold forming and cold extrusion applications. It is favored due to its extreme hardness, wear resistance, and ability to perform under high-pressure conditions, which make it ideal for high-volume production environments. Unlike other materials, tungsten carbide dies can withstand the immense stress, heat, and friction generated during metal forming, allowing manufacturers to achieve long tool life, precision, and productivity.

The primary advantage of tungsten carbide over other die materials (such as steel) is its hardness. With nearly twice the hardness of steel, tungsten carbide ensures that dies remain sharp and effective over long production runs, which helps reduce maintenance costs and increases tool life.

One of the greatest advantages of tungsten carbide dies is their ability to endure high wear and stress without significant degradation. Cold extrusion and cold forming processes involve significant material deformation, and tungsten carbide dies can maintain their integrity even under extreme conditions. As a result, tungsten carbide dies provide consistent part quality over extended production cycles, allowing manufacturers to maintain high throughput while minimizing tool replacement.

The longevity of tungsten carbide dies also reduces downtime, which is critical in high-volume production environments. Since they can handle high-pressure and high-speed operations, tungsten carbide dies ensure a more reliable and efficient production process, leading to increased productivity and reduced operational costs.

By reducing rework, improving cycle times, and maintaining part consistency, tungsten carbide dies help to maximize productivity in cold extrusion. These dies can form complex shapes with high precision, ensuring that each part meets the necessary specifications without the need for additional machining. The extended tool life also contributes to less downtime for die replacements, which is crucial for industries that operate on tight deadlines and high-output requirements.

High-Precision Components for the Automotive Sector

The automotive industry heavily relies on tungsten carbide dies to produce a wide range of high-strength components, such as fasteners, shafts, suspension parts, and gears. These components require a combination of dimensional accuracy and high strength, both of which tungsten carbide dies are uniquely suited to provide. The hardness of tungsten carbide ensures that parts are formed accurately and consistently, even during high-volume production runs.

Automotive parts are often subjected to extreme conditions, and ensuring that each part meets safety, performance, and longevity requirements is crucial. Tungsten carbide dies excel at maintaining precision while withstanding the stresses of high-speed manufacturing, ensuring that the end products meet stringent quality standards.

By utilizing tungsten carbide dies, manufacturers can reduce scrap rates, improving both material usage and overall efficiency. The high wear resistance of tungsten carbide reduces the frequency of tool replacements, lowering operational costs and downtime in production lines. This durability leads to significant long-term savings, especially in high-volume automotive production settings, where reducing downtime and maximizing output is essential.

Lightweight and High-Precision Parts for Aerospace

The aerospace and defense industries require components that are lightweight, yet exceptionally strong and durable. Tungsten carbide dies are ideal for producing small, lightweight parts like connectors, fasteners, and precision structural components used in aerospace applications.

In aerospace manufacturing, parts are subject to extreme operational conditions. Therefore, maintaining tight tolerances and ensuring the structural integrity of each component is critical. Tungsten carbide dies deliver the necessary dimensional accuracy and strength, ensuring these parts meet safety and performance standards required by the aerospace industry.

The high precision and dimensional stability of tungsten carbide dies are crucial for producing components that can withstand extreme temperatures, high pressure, and harsh environments. The reliability of these dies guarantees that parts perform to exact specifications, minimizing the risk of defects or failures in critical aerospace and defense applications.

Precision in Micro-Component Production

In the electronics and medical device manufacturing industries, tungsten carbide dies are essential for producing micro-components that require high precision and consistency. These industries rely on tungsten carbide dies to produce parts such as connectors, pins, and other small components used in medical devices and electronic assemblies.

Tungsten carbide dies offer the necessary precision to meet the strict tolerance requirements for micro-sized components. In both electronics and medical devices, even the smallest defect can lead to product failure, making the precision provided by tungsten carbide dies invaluable.

By using tungsten carbide dies, manufacturers in these sectors achieve consistent quality and ensure the production of parts with fine tolerances. This consistency is critical in medical and electronic applications where functionality, reliability, and safety are paramount.

Tungsten carbide dies are incredibly versatile, making them ideal for use in a wide range of industries. From automotive parts to small electronic components, tungsten carbide dies offer performance and reliability across various forming applications. Their ability to withstand high-stress environments, maintain precision, and provide durability ensures that they meet the specific requirements of different sectors.

In industries such as automotive, aerospace, electronics, and medical devices, tungsten carbide dies consistently outperform other materials due to their superior hardness and wear resistance. Their versatility makes them the preferred choice for manufacturers looking for tools that can handle complex and high-precision forming operations.

High-speed steel (HSS) has been traditionally used in cold forming applications, but it doesn’t match tungsten carbide when it comes to wear resistance and tool life. Tungsten carbide dies can withstand higher levels of friction and pressure, which makes them ideal for high-stress, high-volume operations. HSS dies, although tough, wear out much faster, leading to increased maintenance and more frequent tool replacements.

Tungsten carbide dies provide longer lifespan and greater cost-effectiveness over time, especially in high-volume production where consistent output and tool reliability are critical.

Tool steel is another material commonly used for dies but generally lacks the wear resistance and durability offered by tungsten carbide. While tool steel is more affordable, it tends to wear out quickly when exposed to high-pressure cold forming environments. Tungsten carbide dies, on the other hand, provide superior precision and longer tool life, making them ideal for high-volume cold extrusion and cold forming applications.

Material Type | Hardness | Wear Resistance | Toughness | Ideal Use Case |

Tungsten Carbide | Very High | Very High | Low | High-wear, high-stress applications |

High-Speed Steel | High | Medium | High | Applications requiring good toughness |

Tool Steel | Medium | Low | Medium | Low to medium production runs, less demanding |

Although tungsten carbide dies come with a higher initial cost, their extended lifespan, reduced maintenance, and consistent performance lead to significant long-term savings. By investing in tungsten carbide dies, manufacturers can achieve better ROI through fewer die replacements, less downtime, and improved productivity.

Although tungsten carbide dies are highly durable, challenges such as misalignment, die cracking, and premature wear can occur, especially under extreme conditions. However, tungsten carbide’s resistance to wear and deformation helps mitigate these issues, ensuring that the die performs reliably over time.

To extend the life of tungsten carbide dies, it is essential to implement proper maintenance procedures. This includes regular inspections, proper lubrication, and correct alignment. Choosing the right carbide grade for specific applications is also critical for ensuring the die can handle the stresses it will face during cold forming or cold extrusion operations.

To ensure optimal performance and extend the lifespan of tungsten carbide dies, manufacturers should follow preventative maintenance practices, which include regular checks for wear, ensuring proper lubrication, and preventing misalignment. Proper handling and storage also help maintain die quality over time.

Tungsten carbide dies are essential for high-volume cold forming and cold extrusion applications. Their superior hardness, wear resistance, and dimensional stability make them ideal for industries like automotive, aerospace, and electronics, where precision, durability, and high production rates are essential. By choosing tungsten carbide dies, manufacturers can improve production efficiency, reduce downtime, and enhance product consistency, leading to long-term cost savings and superior performance.

Kunshan Yuntai Precision Mold Co., Ltd. specializes in providing high-quality tungsten carbide dies, offering reliable solutions that improve efficiency and consistency in high-volume manufacturing.

A: A tungsten carbide die is a high-hardness tool used in cold forming to shape metals with precision and durability under high pressure.

A: Tungsten carbide dies offer superior wear resistance and longevity, making them ideal for cold extrusion processes that require high precision and high-volume production.

A: Tungsten carbide dies reduce downtime and maintenance costs, allowing faster cycle times and more consistent production in cold forming applications.

A: Tungsten carbide dies maintain their shape and dimensional accuracy even under extreme pressures, ensuring consistent part quality in cold extrusion and cold forming.

A: Industries such as automotive, aerospace, and electronics benefit from tungsten carbide dies due to their precision, durability, and high-volume production capabilities.

A: Tungsten carbide dies offer significantly better wear resistance, longer tool life, and greater precision than high-speed steel or tool steel, making them more cost-effective for high-volume operations.